Chili is an important vegetable and spice in the world and is grown on a large scale all over the world. People choose to dry the chili for long-term preservation. There are two main methods of drying chili: sun-drying and chili dryer drying. The traditional method of drying chili in the sun can no longer meet the needs of many chili growers and chili processing manufacturers. Many customers choose to use chili dryer equipment to dry chili. Improve production efficiency and create greater economic benefits. So what are the chili dryer equipment?

At present, there are four types of commonly used chili dryers, namely mesh belt type chili drying machine, chili drying room, microwave chili drying machine, and vacuum frozen chili drying equipment. Different dryers are suitable for various customers drying requirements, in addition, the size of the equipment can also be customized and processed.

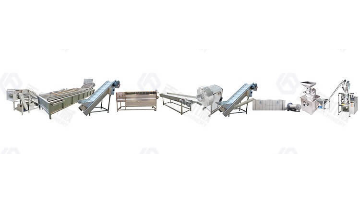

1.Mesh belt type chili dryer:

This is a kind of chili dryer equipment with a relatively large drying output. It can be matched with different heat source methods and materials. It has a fast drying speed and high production efficiency. Common equipment includes mesh belt chili dryer, continuous chili dryer, automatic chili drying machine, special chili dryer, new chili dryer, multifunctional chili dehydrator equipment.

Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying.

The operation temperature is 40-120 degrees centigrade. And the dry cycle is 1-5 hours.

2.Chili drying room:

This is box-type chili dryer equipment. The drying room is equipped with a heat pump dryer to complete the collection and drying of chili heat. Generally, heat pump compressors are used to obtain heat. Large-scale chili drying rooms can also allow chili dryer manufacturers to customize and process other heat sources. Common equipment types: heat pump chili drying room, air energy chili drying room, chili oven, hot air circulation chili room, electric heating chili drying box.

The chili heat pump dryer adopts the principle of reverse Carnot cycle. It absorbs low-temperature heat energy in the air and becomes high-temperature heat energy after efficient heat collection and integration of the heat pump system, which is transported to the drying room to circulate heating and drying the chili, and the hot and humid air in the drying room is directly discharged to the outside of the drying room through the dehumidifier.

3.Microwave chili dryer

This is a new type of chili drying equipment, which uses microwaves to dry chili, and the drying can be completed in a few minutes. The dried chili has good color and complete nutrition retention. Common types of drying equipment: microwave chili dryer, chili microwave drying equipment, microwave chili drying equipment, microwave chili drying equipment, chili microwave dryer.

Microwaves are electromagnetic waves at a frequency of 300 MHz to 300 GHz. The material in the heating medium in the molecules of water is a polar molecule. It is the rapidly changing under high-frequency magnetic field, its polarity orientation will be with the change of external electric field changes, resulting in molecular motion and friction between the effect, this field of the microwave field can be transformed into thermal energy within the medium, the temperature of the material increased, heating and puffing a series of physical and chemical processes, so as to achieve the purpose of microwave heating and drying.

4.Chili vacuum freeze drying equipment:

The principle of this chili drying equipment is to first freeze the chilis quickly, and then vaporize the solid ice in a vacuum state to complete the drying.

The above are the chili dryers commonly used in the chili drying process. You can choose the appropriate type of chili dryer equipment according to your actual needs.

If you want to know more information about chili dryer, please contact us

-

Chili Mesh Belt Dryer200-5000kg/h chili drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

Chili Mesh Belt Dryer200-5000kg/h chili drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection -

Chili Drying Oven50-2000kg/batch chili drying machine/Easy operation/Clean and sanitary/Wide application/Flexible heat source selection

Chili Drying Oven50-2000kg/batch chili drying machine/Easy operation/Clean and sanitary/Wide application/Flexible heat source selection -

Pepper Mesh Belt Dryer200-5000kg/h pepper drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

Pepper Mesh Belt Dryer200-5000kg/h pepper drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

-

Chili DryerProduct Type :Continuous multi-layer mesh belt dryerOutput :200-3000kg/hDrying Time :0.5h-5hTemperature40-120℃Power Input :23KW-150KWHeat Source :Coal,wood chips,natural gas,diesel,propane,electricity etcThis multi-layer mesh belt chili dryer is a continuous convective drying processor of which the chili drying takes place on ventilated conveyor belts. The dryer is featured with fast-drying, high evaporation strength, good product quality. lt is the best choice for large-scale chili drying.View Equipment

Chili DryerProduct Type :Continuous multi-layer mesh belt dryerOutput :200-3000kg/hDrying Time :0.5h-5hTemperature40-120℃Power Input :23KW-150KWHeat Source :Coal,wood chips,natural gas,diesel,propane,electricity etcThis multi-layer mesh belt chili dryer is a continuous convective drying processor of which the chili drying takes place on ventilated conveyor belts. The dryer is featured with fast-drying, high evaporation strength, good product quality. lt is the best choice for large-scale chili drying.View Equipment -

Chili DehydratorProduct Type :All-in-one DehydratorOutput :50-1000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity, Coal,Wood chips,Natural gas, etcCommercial & industrial All-in-one chili dehydrators are the world’s most versatile food dryer machine. They are durable and ideal for small to large businesses that dry fruits and vegetables, flowers and leaves, meats and pet treats, herbs and spices, nuts and seeds, seafood for sale.View Equipment

Chili DehydratorProduct Type :All-in-one DehydratorOutput :50-1000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity, Coal,Wood chips,Natural gas, etcCommercial & industrial All-in-one chili dehydrators are the world’s most versatile food dryer machine. They are durable and ideal for small to large businesses that dry fruits and vegetables, flowers and leaves, meats and pet treats, herbs and spices, nuts and seeds, seafood for sale.View Equipment -

Pepper Drying MachineProduct Type :Hot air drying ovenOutput :50-2000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity,coal,wood chips,natural gas,diesel,propane etcThe industrial pepper drying machine adopts medium and low temperature for drying, After drying, the pepper's original color, shape, and nutrient content can be completely retained.View Equipment

Pepper Drying MachineProduct Type :Hot air drying ovenOutput :50-2000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity,coal,wood chips,natural gas,diesel,propane etcThe industrial pepper drying machine adopts medium and low temperature for drying, After drying, the pepper's original color, shape, and nutrient content can be completely retained.View Equipment -

Spice Microwave DryerProduct Type :Microwave Drying EquipmentOutput :100-2000kg/hDrying Time :0.5h-3hPower Supply :380VPower Input :6KW-200KWHeat Source :ElectricityThe microwave dryer has the function of thawing, sterilizing, curing, and drying. The color and nutritional content of the material remain unchanged. Drying is about 2-3 minutes, the drying time is fast, and the drying is even. It is used to dry food medicinal materials, wood, building materials, cardboard.View Equipment

Spice Microwave DryerProduct Type :Microwave Drying EquipmentOutput :100-2000kg/hDrying Time :0.5h-3hPower Supply :380VPower Input :6KW-200KWHeat Source :ElectricityThe microwave dryer has the function of thawing, sterilizing, curing, and drying. The color and nutritional content of the material remain unchanged. Drying is about 2-3 minutes, the drying time is fast, and the drying is even. It is used to dry food medicinal materials, wood, building materials, cardboard.View Equipment