HOT PRODUCTS

COANTCT US

Sweet Potato Dehydration

3,520

How to dry sweet potato?

By BAIXIN vegetable dehydrator

Ingredients:

Sweet Potato

Directions :

01

Sweet potato is a kind of dried vegetable that people like very much. Baixin sweet potato dryer can be divided into multiple stages to dry fresh sweet potatoes at medium and low temperatures so that the drying effect of sweet potatoes is better. Dried sweet potato will not change any of its nutritional value. The aroma of sweet potato is preserved and the taste is better.

02

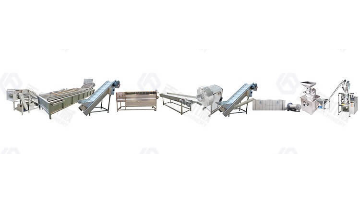

Clean the sweet potatoes first. If the output is large, it is recommended to use a professional sweet potato washing machine.

03

Then put the sweet potatoes into the boiler for cooking. Take out the sweet potatoes when they are about seven or eight ripe.

04

Wait until it is cooled before slicing. Keep the thickness consistent, basically about 2 cm is more appropriate (use a professional slicer).

05

After completing the above steps, you can put the sweet potato chips into the material tray, spread the thickness of the material evenly, and place it neatly. If a mesh belt dryer is used, automatic feeding can be realized.

06

The dryer is turned on. When the temperature of the drying room reaches 30°C, push the material truck filled with sweet potato chips into the drying room, and set the target temperature to 40°C for 2 hours. Entering the second stage, the target temperature is set to 55°C, the drying time is set to 2 hours, and continuous dehumidification is performed. In the third stage, the target temperature is raised to 65°C, the drying time is set for 2 hours, and continuous dehumidification is performed. Entering the fourth stage, the target temperature is set to 70°C, the drying time is set to 2 hours, and continuous dehumidification is performed. Finally, the humidity of the sweet potato chips is maintained at 18%, and the drying is complete. After the shutdown, let the sweet potato chips cool naturally. If you use a mesh belt dryer, the drying time is 2-5 hours.

07

Different processes, different drying methods. You can set the parameters according to your own process. Different sweet potato thickness will have different dehydration time, the thinner, the shorter the dehydration time. Dry sweet potato chips will regain moisture when in direct contact with air, so they need to be sealed and packaged. If you use vacuum packaging, you can better preserve the color and aroma of sweet potatoes.