Pepper is an important vegetable and spice, and it is the most planted crop in the world. Because of the high output of pepper and the large market demand, it is deeply loved by customers. Today, let’s talk about the drying process of pepper? How to choose a pepper dryer?

What are the drying processes of peppers?

At present, when we dry peppers, we use the sun to dry or use drying equipment to dry the peppers. Different pepper drying methods and processes are different, and the drying effect is also very different.

Sun drying of peppers:

The traditional drying method of this pepper is to spread the picked peppers on a clean flat ground, and use the sun and wind to evaporate the water of the peppers. This traditional way of drying peppers is economical and requires little investment. However, because the drying effect is greatly affected by the environment and is not easy to control, the drying color of peppers is uneven, and even defective peppers may appear. Due to the influence of weather conditions, it is easy to cause uneven drying of peppers, and it is easy to mold and deteriorate in the later stage. The drying cycle of peppers is relatively long, and at the same time, the crushing rate of peppers is relatively high. During the drying process of peppers, a certain amount of manpower is required to constantly turn over and dry.

Pepper dryer drying:

This drying method uses pepper drying equipment to reasonably dehydrate the peppers. At present, there are more pepper drying rooms and mesh belt type pepper dryers. The pepper drying room is more suitable for small batch pepper drying processing, and the mesh belt type pepper drying machine is more suitable for batch continuous large-scale pepper drying processing.

If we are using a pepper drying room, then this equipment has a built-in trolley, and the trolley has trays and tray racks. When drying the peppers, we spread the peppers on the tray and put them on the trolley. On the tray rack, and then push it into the pepper drying room for drying processing. The heat source of this pepper drying room is air. The heat in the air is absorbed by the heat pump compressor. After compression and release, a large amount of high-temperature hot air can be obtained, so as to achieve continuous and uniform drying and processing of peppers.

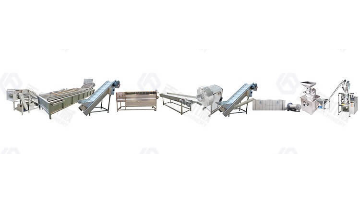

If we are using a mesh belt type pepper dryer, then this equipment has a wide range of heat sources, such as coal heating, gas heating, steam heating, biomass pellet heating, or electric heating. It is a multi-layer continuous drying structure. The peppers are dried and dehydrated layer by layer from top to bottom. The drying speed is fast and the production efficiency is high. It is very suitable for the drying and processing of large quantities of peppers.

How to choose a pepper dryer?

Having said so many chili drying processes, let me briefly talk about how to choose a chili dryer. Because the pepper drying equipment we use at present are all non-standard equipment, different manufacturers have different drying technology and equipment quality, so we can choose according to our actual situation, combined with the strength of the manufacturer, Comprehensive consideration and analysis of equipment quality, production efficiency, drying cost, etc., to choose the suitable pepper drying equipment for us.

Small production pepper drying recommended purchase: drying box

Medium-yield pepper drying recommended purchase: pepper drying room

Large-capacity pepper drying recommended purchase: continuous mesh belt dryer

-

Chili Mesh Belt Dryer200-5000kg/h chili drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

Chili Mesh Belt Dryer200-5000kg/h chili drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection -

Chili Drying Oven50-2000kg/batch chili drying machine/Easy operation/Clean and sanitary/Wide application/Flexible heat source selection

Chili Drying Oven50-2000kg/batch chili drying machine/Easy operation/Clean and sanitary/Wide application/Flexible heat source selection -

Pepper Mesh Belt Dryer200-5000kg/h pepper drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

Pepper Mesh Belt Dryer200-5000kg/h pepper drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

-

Chili DryerProduct Type :Continuous multi-layer mesh belt dryerOutput :200-3000kg/hDrying Time :0.5h-5hTemperature40-120℃Power Input :23KW-150KWHeat Source :Coal,wood chips,natural gas,diesel,propane,electricity etcThis multi-layer mesh belt chili dryer is a continuous convective drying processor of which the chili drying takes place on ventilated conveyor belts. The dryer is featured with fast-drying, high evaporation strength, good product quality. lt is the best choice for large-scale chili drying.View Equipment

Chili DryerProduct Type :Continuous multi-layer mesh belt dryerOutput :200-3000kg/hDrying Time :0.5h-5hTemperature40-120℃Power Input :23KW-150KWHeat Source :Coal,wood chips,natural gas,diesel,propane,electricity etcThis multi-layer mesh belt chili dryer is a continuous convective drying processor of which the chili drying takes place on ventilated conveyor belts. The dryer is featured with fast-drying, high evaporation strength, good product quality. lt is the best choice for large-scale chili drying.View Equipment -

Chili DehydratorProduct Type :All-in-one DehydratorOutput :50-1000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity, Coal,Wood chips,Natural gas, etcCommercial & industrial All-in-one chili dehydrators are the world’s most versatile food dryer machine. They are durable and ideal for small to large businesses that dry fruits and vegetables, flowers and leaves, meats and pet treats, herbs and spices, nuts and seeds, seafood for sale.View Equipment

Chili DehydratorProduct Type :All-in-one DehydratorOutput :50-1000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity, Coal,Wood chips,Natural gas, etcCommercial & industrial All-in-one chili dehydrators are the world’s most versatile food dryer machine. They are durable and ideal for small to large businesses that dry fruits and vegetables, flowers and leaves, meats and pet treats, herbs and spices, nuts and seeds, seafood for sale.View Equipment -

Pepper Drying MachineProduct Type :Hot air drying ovenOutput :50-2000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity,coal,wood chips,natural gas,diesel,propane etcThe industrial pepper drying machine adopts medium and low temperature for drying, After drying, the pepper's original color, shape, and nutrient content can be completely retained.View Equipment

Pepper Drying MachineProduct Type :Hot air drying ovenOutput :50-2000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity,coal,wood chips,natural gas,diesel,propane etcThe industrial pepper drying machine adopts medium and low temperature for drying, After drying, the pepper's original color, shape, and nutrient content can be completely retained.View Equipment -

Spice Microwave DryerProduct Type :Microwave Drying EquipmentOutput :100-2000kg/hDrying Time :0.5h-3hPower Supply :380VPower Input :6KW-200KWHeat Source :ElectricityThe microwave dryer has the function of thawing, sterilizing, curing, and drying. The color and nutritional content of the material remain unchanged. Drying is about 2-3 minutes, the drying time is fast, and the drying is even. It is used to dry food medicinal materials, wood, building materials, cardboard.View Equipment

Spice Microwave DryerProduct Type :Microwave Drying EquipmentOutput :100-2000kg/hDrying Time :0.5h-3hPower Supply :380VPower Input :6KW-200KWHeat Source :ElectricityThe microwave dryer has the function of thawing, sterilizing, curing, and drying. The color and nutritional content of the material remain unchanged. Drying is about 2-3 minutes, the drying time is fast, and the drying is even. It is used to dry food medicinal materials, wood, building materials, cardboard.View Equipment