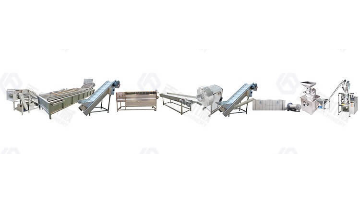

Introduction of the ginger powder production line

The ginger powder processing line uses ginger as raw material and processes ginger into ginger powder through processing techniques such as cleaning, peeling, slicing, drying, and grinding. Meet the culinary needs of different households, restaurants, and food processing plants.

Processing ginger into ginger powder can increase the added value of ginger in the ginger planting industry, and reduce the ginger loss and storage and transportation costs caused by ginger price fluctuations. This is the best choice for the ginger powder business!

Components of ginger powder processing line

Ginger cleaning machine: It is used to clean the dirt, dust, and other impurities attached to the surface of ginger root. The ginger is rolled, washed, and transported under the action of high-pressure water flow and powerful air bubbles, and then sent to the next process.

Ginger peeler: for cleaning and removing the epidermis. The specially designed screw feeding structure is adopted to realize fully automatic work.

Ginger slicer: The thickness of ginger slices is uniform, and the slice thickness can be adjusted as needed.

Ginger air dryer: effectively remove the moisture on the surface of ginger slices after cleaning, greatly shorten the drying cycle, suitable for assembly line operation.

Ginger slice dryer: adopts multi-layer moving stainless steel mesh belt, automatic loading, and unloading, saving a lot of labor costs. Flexible heat source selection: Coal, wood chips, natural gas, diesel, propane, electricity, etc.

Ginger powder making machine: Grind dried ginger slices to a fineness of 10-120 mesh. The ginger grinder is air-cooled or water-cooled and can work continuously for a long time.

Ginger powder packaging machine: Generally speaking, the ginger powder business requires automatic ginger powder packaging equipment. The ginger powder packaging machine has a PLC control system, which is intelligent and controllable and can be quickly adjusted according to customer packaging requirements. Packaging weight and quantity are automatically adjusted.

Advantages of ginger powder processing line

| 500-800kg/h automatic ginger powder processing line | ||||

| Number | Name | Power | Size | Output |

| 1 | Cleaning hoist | 0.37KW | 3200*1050*2500mm | 500-1000kg/h |

| 2 | Bubble cleaning machine | 3.37KW | 3000*1020*1350mm | 1000kg/h |

| 3 | Hoist | 0.55KW | 1500*800*1600mm | 500-1000kg/h |

| 4 | Cleaning and peeling machine | 2.75KW | 3050*700*1600mm | 1000kg/h |

| 5 | Picking table | 0.37KW | 3000*740*1100mm | 500-1000kg/h |

| 6 | Slicer | 1.1KW | 690*560*880mm | 500kg/h |

| 7 | Hoist | 0.55KW | 1500*800*1600mm | 500-1000kg/h |

| 8 | Dryer | 20.12KW | 9000*2000*2500mm | 500-800kg/h |

| 9 | Grinder | 15KW | 1200*1000*2000mm | 500-700kg/h |

| 10 | Packing Machine | 3.5KW | 3000*1500*2600mm | 30-60 packs/min |

| The ginger powder processing line can be equipped according to the user’s requirement and the production demands. | ||||