Hot air circulation chili dryer is a relatively common chili drying equipment. When many customers inquire about chili drying equipment, in addition to asking about the price of a chili dryer, what they ask more is the chili drying time. Below we will tell you how long it takes to dry chili with the actual drying experience and data of hundreds of chili drying cases.

For the drying time of chili, the different styles, models, and output of equipment produced by different manufacturers will cause different time and drying effects when drying chili. Take the chili drying equipment produced by our Baixin Machinery Factory as an example, which can be divided into large mesh belt chili dryers and small and medium heat pump chili drying rooms, which can dry fresh chili from 200 kg to 50 tons per day.

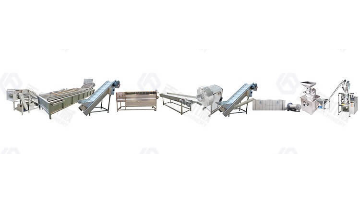

The emergence of the large belt type chili dryer is to meet the demand for drying output, which can achieve 24-hour continuous drying. It only takes 4 hours from feeding to fast discharging. The equipment is applied through a multi-layer stainless steel mesh belt with a cyclic overturn structure, so that the dried chili is dried evenly. The equipment is automated and intelligent.

Working principle of chili mesh belt dryer:

Chili mesh belt dryer machine is a kind of continuous production drying equipment, the main heating way has electric heating, steam heating, hot air heating. Its main working principle is to spread the material evenly in the network. The material is moved in the dryer by the operation of the machine, and the hot air draws out the water vapor of the material. so as to achieve the purpose of drying.

The operation temperature is 40-120 degrees centigrade. And the dry cycle is 1-5 hours.

Small and medium-sized heat pump drying rooms use intermittent drying, which can be dried in stages, which can further improve the quality of chili, and the drying time can be accurately controlled within 6-20 hours, because the use of heat pump dryers as heat sources can accurately It can control the temperature and humidity, so that the drying parameters such as time, temperature, humidity, and air volume can be set for the chili in the drying room.

Working principle of chili drying oven:

The chili heat pump dryer adopts the principle of reverse Carnot cycle. It absorbs low-temperature heat energy in the air and becomes high-temperature heat energy after efficient heat collection and integration of the heat pump system, which is transported to the drying room to circulate heating and drying the chili, and the hot and humid air in the drying room is directly discharged to the outside of the drying room through the dehumidifier.

The chili heat pump dryer can quickly remove the water in the chili without affecting the original color, shape, and nutrient content of the chili. The chili drying oven is equipped with a computer control system, which can realize automatic temperature control. The drying temperature range of the heat pump dryer is 20-80°C.

The drying time for different chili varieties is also different. Some chili has thick flesh and different water content, which makes it difficult to dry, and the required drying time may be longer.

The use of chili will also affect the drying time. Some chili is dried entirely, and some chili is cut and dried; the time required for cutting and drying chili is shorter than the time required for drying the whole chili.

-

Chili Mesh Belt Dryer200-5000kg/h chili drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

Chili Mesh Belt Dryer200-5000kg/h chili drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection -

Chili Drying Oven50-2000kg/batch chili drying machine/Easy operation/Clean and sanitary/Wide application/Flexible heat source selection

Chili Drying Oven50-2000kg/batch chili drying machine/Easy operation/Clean and sanitary/Wide application/Flexible heat source selection -

Microwave black soldier fly larvae sterilization and drying machine200-5000kg/h larva drying machine/Fast dehydration/continuous automatic work/easy operation/

Microwave black soldier fly larvae sterilization and drying machine200-5000kg/h larva drying machine/Fast dehydration/continuous automatic work/easy operation/

-

Chili DryerProduct Type :Continuous multi-layer mesh belt dryerOutput :200-3000kg/hDrying Time :0.5h-5hTemperature40-120℃Power Input :23KW-150KWHeat Source :Coal,wood chips,natural gas,diesel,propane,electricity etcThis multi-layer mesh belt chili dryer is a continuous convective drying processor of which the chili drying takes place on ventilated conveyor belts. The dryer is featured with fast-drying, high evaporation strength, good product quality. lt is the best choice for large-scale chili drying.View Equipment

Chili DryerProduct Type :Continuous multi-layer mesh belt dryerOutput :200-3000kg/hDrying Time :0.5h-5hTemperature40-120℃Power Input :23KW-150KWHeat Source :Coal,wood chips,natural gas,diesel,propane,electricity etcThis multi-layer mesh belt chili dryer is a continuous convective drying processor of which the chili drying takes place on ventilated conveyor belts. The dryer is featured with fast-drying, high evaporation strength, good product quality. lt is the best choice for large-scale chili drying.View Equipment -

Chili DehydratorProduct Type :All-in-one DehydratorOutput :50-1000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity, Coal,Wood chips,Natural gas, etcCommercial & industrial All-in-one chili dehydrators are the world’s most versatile food dryer machine. They are durable and ideal for small to large businesses that dry fruits and vegetables, flowers and leaves, meats and pet treats, herbs and spices, nuts and seeds, seafood for sale.View Equipment

Chili DehydratorProduct Type :All-in-one DehydratorOutput :50-1000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity, Coal,Wood chips,Natural gas, etcCommercial & industrial All-in-one chili dehydrators are the world’s most versatile food dryer machine. They are durable and ideal for small to large businesses that dry fruits and vegetables, flowers and leaves, meats and pet treats, herbs and spices, nuts and seeds, seafood for sale.View Equipment -

Pepper Drying MachineProduct Type :Hot air drying ovenOutput :50-2000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity,coal,wood chips,natural gas,diesel,propane etcThe industrial pepper drying machine adopts medium and low temperature for drying, After drying, the pepper's original color, shape, and nutrient content can be completely retained.View Equipment

Pepper Drying MachineProduct Type :Hot air drying ovenOutput :50-2000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity,coal,wood chips,natural gas,diesel,propane etcThe industrial pepper drying machine adopts medium and low temperature for drying, After drying, the pepper's original color, shape, and nutrient content can be completely retained.View Equipment -

Spice Microwave DryerProduct Type :Microwave Drying EquipmentOutput :100-2000kg/hDrying Time :0.5h-3hPower Supply :380VPower Input :6KW-200KWHeat Source :ElectricityThe microwave dryer has the function of thawing, sterilizing, curing, and drying. The color and nutritional content of the material remain unchanged. Drying is about 2-3 minutes, the drying time is fast, and the drying is even. It is used to dry food medicinal materials, wood, building materials, cardboard.View Equipment

Spice Microwave DryerProduct Type :Microwave Drying EquipmentOutput :100-2000kg/hDrying Time :0.5h-3hPower Supply :380VPower Input :6KW-200KWHeat Source :ElectricityThe microwave dryer has the function of thawing, sterilizing, curing, and drying. The color and nutritional content of the material remain unchanged. Drying is about 2-3 minutes, the drying time is fast, and the drying is even. It is used to dry food medicinal materials, wood, building materials, cardboard.View Equipment