Nowadays, the production of peppers in the world is increasing, and the traditional method of drying peppers in the sun can no longer meet everyone’s needs, so everyone uses chili dryer equipment for processing. Different types of chili dryer equipment are different, and chili drying processes also have differences, today we will talk about chili drying equipment and chili drying process, hoping to give you some references.

At present, there are mainly two types of chili drying equipment: chili drying room and mesh belt chili drying machine. One of these two types is static chili drying, and the other is dynamic chili drying processing method. Next, let us introduce to you:

Drying process of chili drying room:

The chili drying room is a new type of energy-saving chili drying equipment that integrates ventilation, heating and moisture removal. It consists of a heat pump host, an insulation board room, a circulating fan, etc. Utilization rate, durability and good stability, which greatly saves operating costs, and different sizes of chili drying room equipment can be used for different output.

The heat pump chili drying room equipment uses electricity as a heat source, and by driving the heat pump compressor, absorbs a large amount of heat in the air energy, compresses and releases it, and obtains a large amount of high-temperature hot air, and a large amount of hot air circulates in the box. After continuous fresh air supply enters the box from the air inlet, and then continuously discharges from the moisture exhaust port, which increases the heat transfer effect, gradually reduces the moisture of the chili in the box, and completes the drying process. In the chili drying room, there are multiple trolleys and tray rack structures, which can achieve the purpose of fast-drying of chili.

Processing steps of chili drying room:

1: pick chili:

Due to the different quality and maturity of chili, unsuitable chili should be selected before drying.

2: clean the chili:

To clean the surface dust of chili, if the output is large, it is recommended to use a professional chili cleaning machine.

3: chili punching or cutting:

Poke some small holes in the chili (green chili needs to be sliced) to shorten the drying time. If the output is large, it is recommended to use a professional chili puncher. If you need to dry the whole chili, you don’t need this step.

4: Put the chili on the tray:

Spread the chili evenly on the tray with a thickness of about 5 cm, and then put them in the drying oven.

5: chili drying:

Set the temperature in the drying room to 65°C and the humidity to 10%. Dry for 6~8 hours to complete the chili drying.

6: storage:

The dried chili will regain moisture when they are in direct contact with the air, so a sealed package is required. If you use vacuum packaging, you can better preserve the color and aroma of chili.

Mesh belt chili dryer drying process:

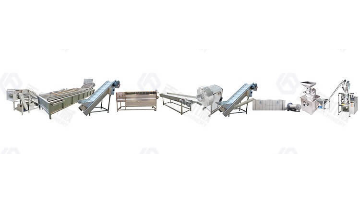

The mesh belt chili dryer, also known as the multi-layer chili dryer, is a special equipment for dehydrating and drying fresh chili. It consists of main components such as heat exchanger and dehumidification fan. It can be applied to the processing of various foods, fruits, and vegetables.

The mesh belt chili dryer mainly uses air as the drying medium, and automatically turns the material during the chili drying process to achieve the purpose of drying. It adopts a scientific and reasonable circulation method and has continuous production, controllable speed, adjustable temperature, and chili. It has the characteristics of uniform drying and no pollution. The hot air is circulated under the action of the circulating fan, and then the air with low temperature and high humidity is discharged, and the whole drying process is stably completed, and the hot air is fully utilized to dry quickly.

Processing steps of pepper multi-layer mesh belt dryer:

1:Place the chili on the conveyor belt of the chili dryer. The chili is spread on the feeder by the homogenizing device on the conveyor belt.The stacking thickness of chili is 10-20CM.

2:After the chili enters the chili dryer, it runs in an “S” shape in the dryer. The transmission part of the chili dryer adopts a variable-frequency speed-regulating motor, which can control the internal operation time of the drying according to the difference of the water content of the chili.

3:The wind speed and wind pressure generated by the hot air blower make the hot air fully and evenly distributed inside the chili dryer. Because the lower pressure is greater than the upper pressure, the hot air naturally moves upward, passing through each layer of the mesh belt, plus the movement and rolling of the chili, Make the chili fully contact with the hot air, fully heat exchange, and improve the drying efficiency. The dried chili will drain through the last layer.

If you want to know more information, please contact us.

-

Chili Mesh Belt Dryer200-5000kg/h chili drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

Chili Mesh Belt Dryer200-5000kg/h chili drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection -

Chili Drying Oven50-2000kg/batch chili drying machine/Easy operation/Clean and sanitary/Wide application/Flexible heat source selection

Chili Drying Oven50-2000kg/batch chili drying machine/Easy operation/Clean and sanitary/Wide application/Flexible heat source selection -

Pepper Mesh Belt Dryer200-5000kg/h pepper drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

Pepper Mesh Belt Dryer200-5000kg/h pepper drying machine/Fast dehydration/continuous automatic work/easy operation/Flexible heat source selection

-

Chili DryerProduct Type :Continuous multi-layer mesh belt dryerOutput :200-3000kg/hDrying Time :0.5h-5hTemperature40-120℃Power Input :23KW-150KWHeat Source :Coal,wood chips,natural gas,diesel,propane,electricity etcThis multi-layer mesh belt chili dryer is a continuous convective drying processor of which the chili drying takes place on ventilated conveyor belts. The dryer is featured with fast-drying, high evaporation strength, good product quality. lt is the best choice for large-scale chili drying.View Equipment

Chili DryerProduct Type :Continuous multi-layer mesh belt dryerOutput :200-3000kg/hDrying Time :0.5h-5hTemperature40-120℃Power Input :23KW-150KWHeat Source :Coal,wood chips,natural gas,diesel,propane,electricity etcThis multi-layer mesh belt chili dryer is a continuous convective drying processor of which the chili drying takes place on ventilated conveyor belts. The dryer is featured with fast-drying, high evaporation strength, good product quality. lt is the best choice for large-scale chili drying.View Equipment -

Chili DehydratorProduct Type :All-in-one DehydratorOutput :50-1000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity, Coal,Wood chips,Natural gas, etcCommercial & industrial All-in-one chili dehydrators are the world’s most versatile food dryer machine. They are durable and ideal for small to large businesses that dry fruits and vegetables, flowers and leaves, meats and pet treats, herbs and spices, nuts and seeds, seafood for sale.View Equipment

Chili DehydratorProduct Type :All-in-one DehydratorOutput :50-1000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity, Coal,Wood chips,Natural gas, etcCommercial & industrial All-in-one chili dehydrators are the world’s most versatile food dryer machine. They are durable and ideal for small to large businesses that dry fruits and vegetables, flowers and leaves, meats and pet treats, herbs and spices, nuts and seeds, seafood for sale.View Equipment -

Pepper Drying MachineProduct Type :Hot air drying ovenOutput :50-2000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity,coal,wood chips,natural gas,diesel,propane etcThe industrial pepper drying machine adopts medium and low temperature for drying, After drying, the pepper's original color, shape, and nutrient content can be completely retained.View Equipment

Pepper Drying MachineProduct Type :Hot air drying ovenOutput :50-2000kg/batchDrying Time :40-100℃Power Supply :220V / 380V / 50HzPower Input :1KW-60KWHeat Source :Electricity,coal,wood chips,natural gas,diesel,propane etcThe industrial pepper drying machine adopts medium and low temperature for drying, After drying, the pepper's original color, shape, and nutrient content can be completely retained.View Equipment -

Spice Microwave DryerProduct Type :Microwave Drying EquipmentOutput :100-2000kg/hDrying Time :0.5h-3hPower Supply :380VPower Input :6KW-200KWHeat Source :ElectricityThe microwave dryer has the function of thawing, sterilizing, curing, and drying. The color and nutritional content of the material remain unchanged. Drying is about 2-3 minutes, the drying time is fast, and the drying is even. It is used to dry food medicinal materials, wood, building materials, cardboard.View Equipment

Spice Microwave DryerProduct Type :Microwave Drying EquipmentOutput :100-2000kg/hDrying Time :0.5h-3hPower Supply :380VPower Input :6KW-200KWHeat Source :ElectricityThe microwave dryer has the function of thawing, sterilizing, curing, and drying. The color and nutritional content of the material remain unchanged. Drying is about 2-3 minutes, the drying time is fast, and the drying is even. It is used to dry food medicinal materials, wood, building materials, cardboard.View Equipment